d3d-S 3d Scanner

0.029 mm/pix resolution with 0.010mm accuracy.

D3D-S 3D Pro scanner has some of the best resolution at 0.029 mm/pix with an accuracy of 0.010 mm, which allows for the scanned object look exactly like the original. The use of Super Retina resolution in the D3D-S scanner results in details that are often invisible to the naked eye.

HighLights

Designed specifically with jewellery and small stones in mind. The D3D-S scanner features a camera that is oriented horizontally.

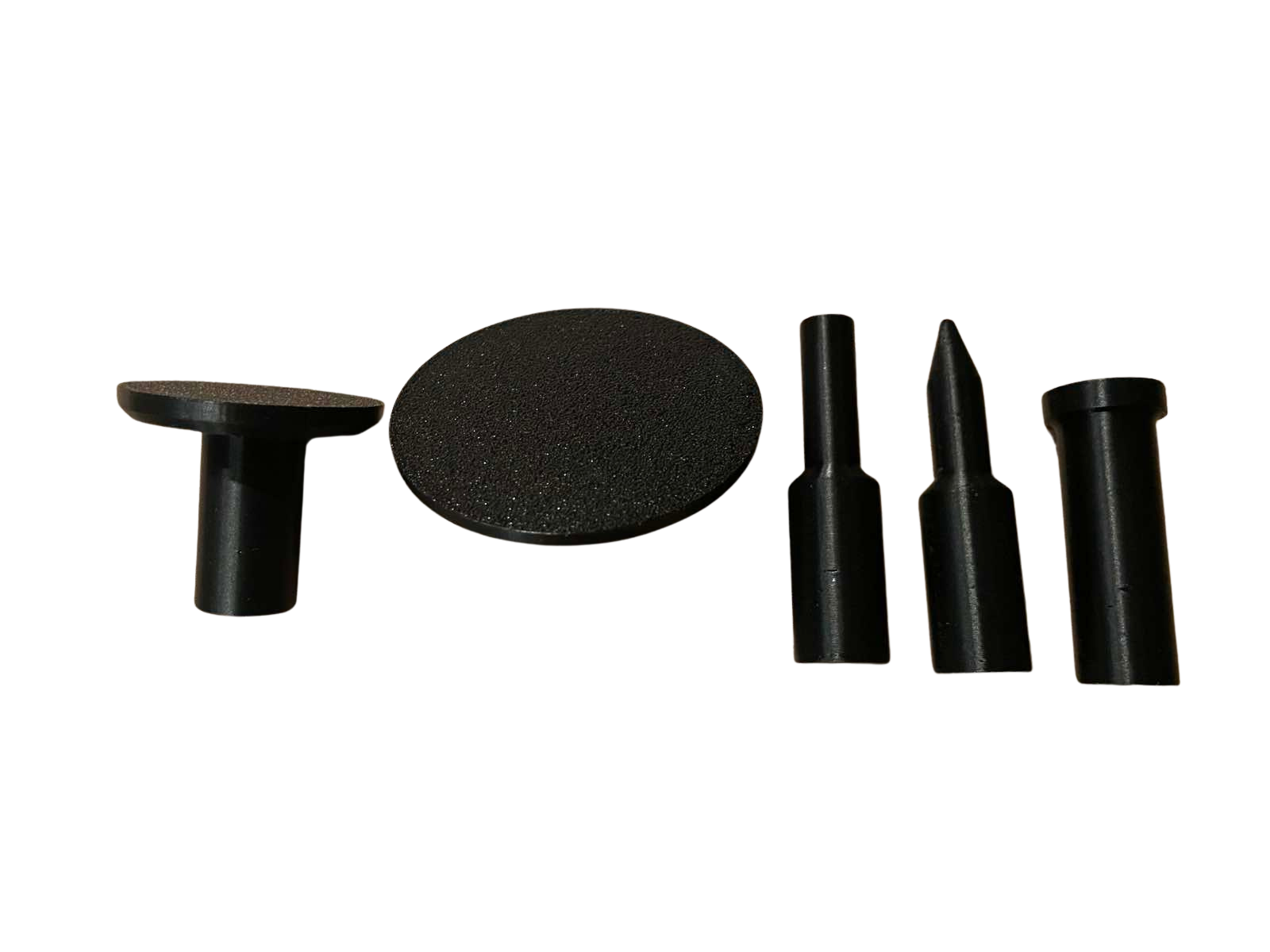

The D3D-S includes specialised attachments which have been designed for scanning gemstones from a single setup, capturing both the top and bottom sides simultaneously.

Pro d3d-s

Work Area: 200 x 100mm

Resolution: 0.029mm/pix

Fixtures: 5

Warranty: 2 Years

Minimum System Requirements

64-bit Windows 8/10/11

16 GB RAM

NVIDIA card with 2 GB RAM

Fast SSD (recommended)

4GB of HDD free space

USB 3.x

Software

Sold with software developed specifically for the D3D-S scanner the software includes lots of unique features. Currently available for Windows 8/10/11. Once the scanning is done, you'll get an STL file that you can open in any program that supports STL files, such as ZBRUSH, RhinoGold, MatrixGold, Jewellery cad dream and more.

Price

$7,450.00 USD excluding GST & local freight from Brisbane

Why Invest in 3D scanning?

Jewellery Creation and Reproduction

Matching Wedding Bands: Precisely craft identical wedding bands by scanning complex surfaces—ideal for replicating intricate details that are hard to measure manually.

Heirloom Replication: Create new jewelry pieces based on existing ones without disassembling the originals, preserving sentimental value.

Gemstone Scanning: Capture the unique shapes and sizes of gemstones to ensure a perfect fit in mountings and bezels.

Art Preservation: Preserve digital copies of valuable or fragile artworks, reproducing sculptures and decorative elements without risking damage.

Design, Repair, and Prototyping

Intricate Repairs: Perform complex jewellery repairs by scanning pieces and designing perfect-fitting components.

Rapid Prototyping: Quickly prototype small parts for industrial design, testing forms and fits before mass production.

Scaling and Modifying: Scan and scale objects to different sizes, saving significant modelling time.

Miniatures and Collectibles

Miniature Scanning: Digitally reproduce miniature figurines for collectibles or tabletop games, creating 3D models for printing or virtual reality.

Coins and Medals: Document and analyse numismatic collections, determining authenticity and assessing item conditions.

Mechanical Components

Watch Parts: Analyse and reproduce small mechanical components of watches, aiding in repair and restoration.

Mechanical Parts Scanning: Reverse-engineer parts for reproduction or modification, ensuring quality control and precision manufacturing.

Keys and Locks: Reproduce complex key structures and analyse the security of locking mechanisms.

The scanning Process

1. Preparation

Before scanning, the object and workspace are prepared:

Clean the object to remove dust, smudges, or fingerprints that might affect the scan.

Positioning: Place the object on a turntable or in a stable, visible location.

Surface treatment (if needed): Shiny, transparent, or dark objects may require a light coating of scanning spray to help the scanner read the surface. This spray is formulated to be non-reflective which results in more accurate scans especially with Jewellery.

2. Scanning

The 3D scanner captures the geometry of the object:

Laser scanning: Projects laser lines or points over the object and measures distortions to record shape.

Structured light scanning: Projects patterned light and records how it deforms over the surface.

Photogrammetry: Takes multiple photographs from different angles and uses software to reconstruct the 3D form.

Multiple passes: The scanner captures different sides of the object by rotating it or moving the scanner around it.

3. Data Capture & Alignment

The scanner’s software:

Records point clouds (millions of points in 3D space) representing the surface.

Aligns multiple scans so that different views merge into one unified 3D dataset.

Removes noise or stray points caused by reflections or background objects.

4. Mesh Generation

The point cloud is converted into a polygon mesh, a continuous 3D surface made of tiny triangles.

Holes or gaps are filled, and surfaces are smoothed if necessary.

For jewellery or precision work, the mesh is kept at high resolution to preserve fine detail.

5. Texture & Colour Mapping

If required:

The scanner also captures surface texture.

These are applied to the mesh for realistic visualisation or design reference.

6. Export & Use

The finished 3D file is exported in formats like STL, OBJ, or PLY.

It can then be used for:

3D printing or casting (e.g., creating wax models for jewellery)

Digital restoration or design modification

Archiving or virtual display